PSTHL PCBA Product Show

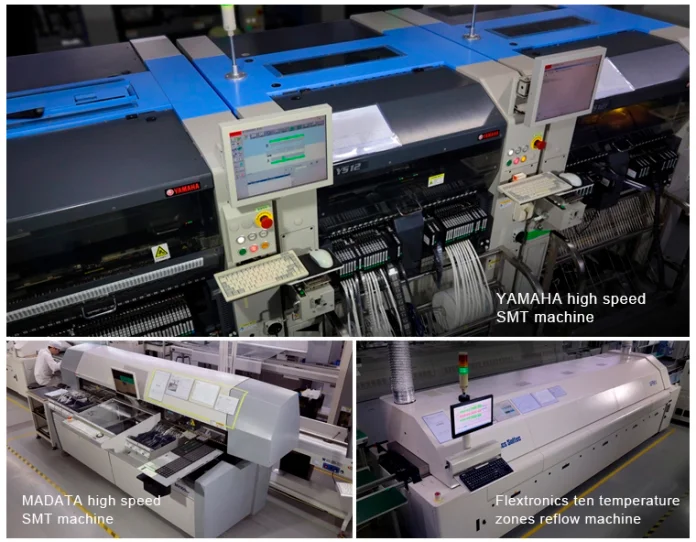

Production equipment:

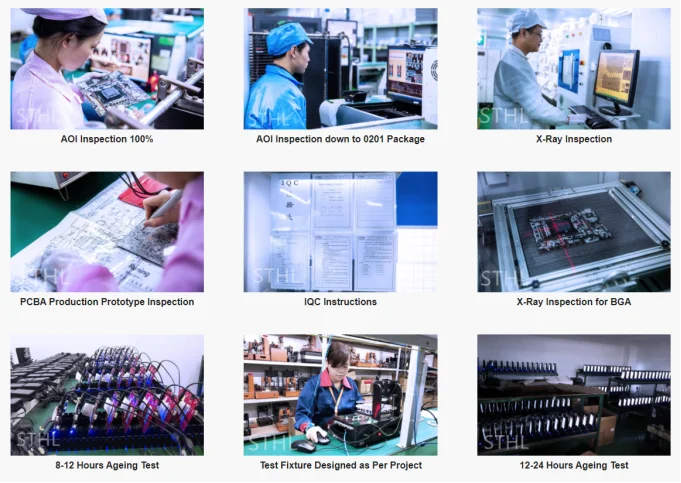

Inspection & Testing at STHL

As an ISO9001 certificated electronics assembly manufacturer, STHL Technology adheres to a thorough quality and process control. The tests and inspections include physical and visual inspections, open & short tests, AOI inspections, X-ray inspection, and In-Circuit tests. We also make ageing testing both for mother board and finished product. These PCBA inspection process ensure customers final product meets their design specifications, and also control the whole production lot to high non-defective ratio which reduce the entire lead time.

Below description help you to know more about PCB Assembly

| Type of Assembly |

SMT,Thru-hole, DIP |

| Solder Type |

Water Soluble Solder Paste,Leaded and Lead-Free |

| Components |

Passive Down to 0201 size |

| BGA and VFBGA |

| Leadless Chip Carriers/CSP |

| Double-sided SMT Assembly |

| Fine Pitch to 0.8mils |

| BGA Repair and Reball |

| Part Removal and Replacement |

| Bare Board Size |

Smallest:0.25*0.25 inches |

| Largest:20*20 inches |

| File Formate |

Bill of Materials |

| Gerber files |

| Pick-N-Place file |

| Types of Service |

Turn-key,partial turn-key or consignment |

| Component packaging |

Cut Tape,Tube,Reels,Loose Parts |

| Turn Time |

Same day service to 15 days service |

| Testing |

X-Ray Inspection AOI Test Function Test |

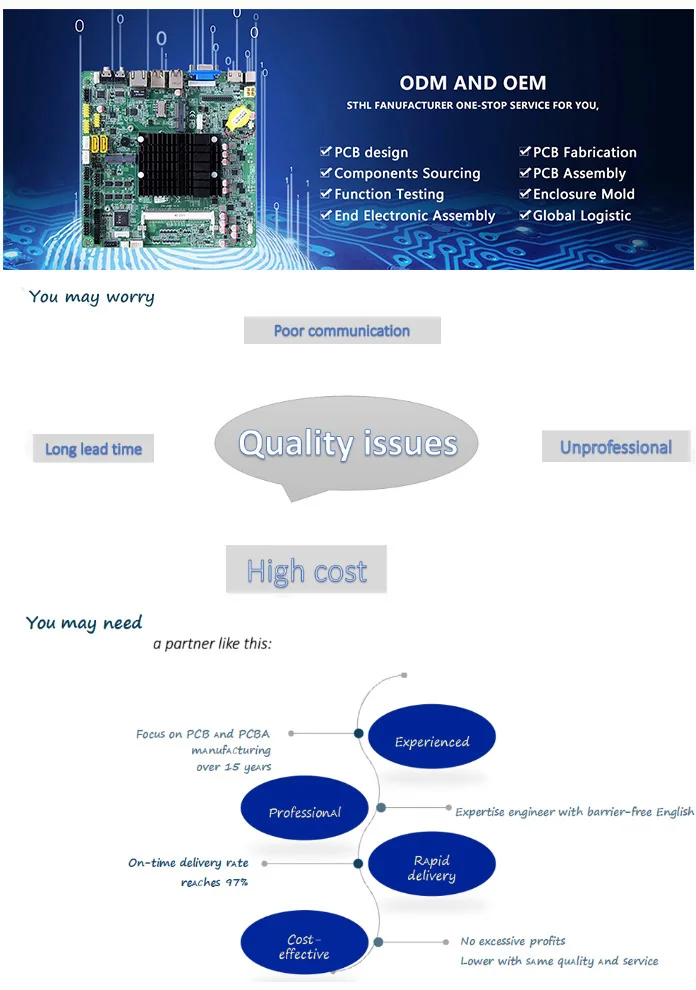

STHL services

STHL management team are 10+ years experience in PCB and PCBA field, our sales representatives are very stable and mostly worked here since the company establish. They can help you remember your projects details and requested. And our engineers can contact with customers directly in English if necessary, the faster and more effective communication helps lead time a lot.

STHL management team are 10+ years experience in PCB and PCBA field, our sales representatives are very stable and mostly worked here since the company establish. They can help you remember your projects details and requested. And our engineers can contact with customers directly in English if necessary, the faster and more effective communication helps lead time a lot.

01 Real Factory

STHL PCBA is a real factory with 4000 SQM production base and 150 employees.

02 Rich Experience

Management team are 10+ years experience in electronics assembly industry.

03 Stable Sales Representatives

STHL PCBA sales representatives are very stable and mostly work for STHL since the company establish. They can help you remember your projects details and requested.

04 Effective Communication

Our engineers can contact with customers directly in English if necessary, the faster and more effective communication is helpful cost saving and lead time.

05 Material Quality Control

We buy components from famous international platform like Mouser, Digikey, Farnell, Future, Avnet, Arrow and branded materials agents. Repeat orders material normally ordered from the same source, we do not change suppliers time by time if everything goes well.

06 Customer Approval First

No components substitutes without customers approval. We know alternatives can save cost, but we don’t want to make one time business. STHL PCBA always looking for long-term business.

07 NDA Agreement

We ensure all of your projects documents security. We can sign NDA agreement before RFQ.

08 Storage Control

Materials store under temperature and moisture control. Clear and strict labeling, baking, recording process.

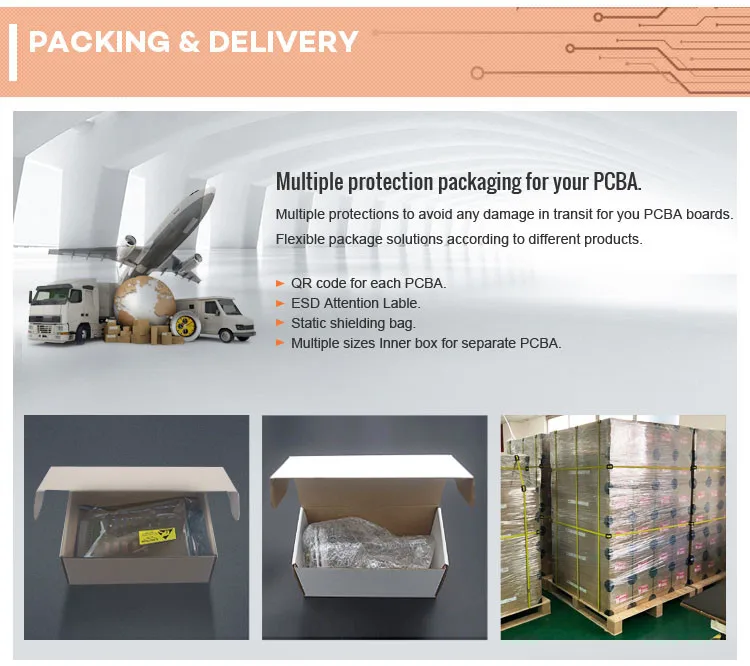

STHL PCBA Packing and Delivery

GET QUOTATION NOW, PLS CONTACT:

Miss Zoe

sales02@firstpcba(dot)com